Prosthetic contact lenses.

Prosthetic contact lenses are remarkable devices that not only restore vision but also improve the appearance of individuals with eye conditions. Behind their creation lies a blend of artistry and scientific precision. In this blog post, we will explore the fascinating process of designing prosthetic contact lenses, from initial consultations to the final product.

1. Understanding the Needs and Goals:

The design process begins with a comprehensive understanding of the patient’s needs and goals. We work closely with patients to assess their specific eye condition, desired appearance, and functional requirements. By listening to their concerns and aspirations, a personalized approach can be crafted.

2. Initial Consultation and Eye Examination:

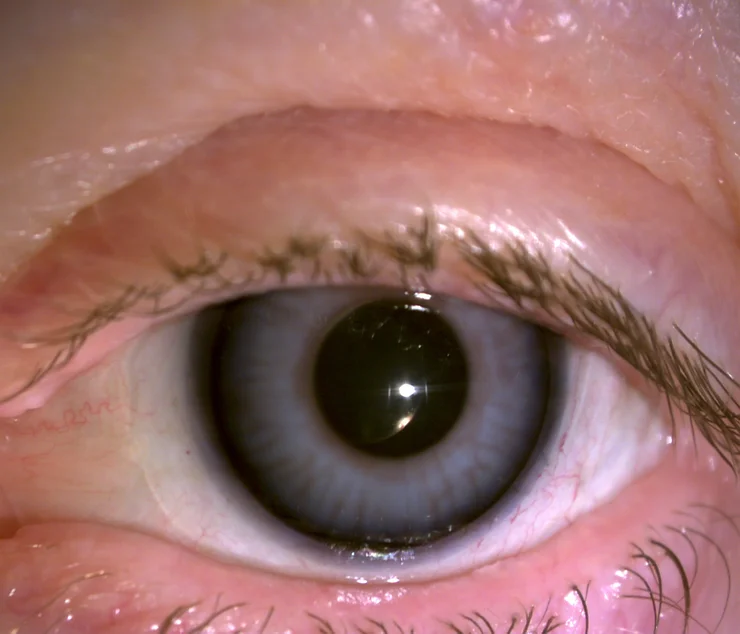

During the initial consultation, eye care professionals conduct a thorough eye examination to gather essential information. This examination includes measuring the curvature of the cornea, assessing the size and shape of the iris, and determining the desired color match. These measurements serve as the foundation for the design process.

3. Advanced Technology and Customization:

With advancements in technology, the design of prosthetic contact lenses has become highly customizable. Specialized software is utilized to create a digital map of the patient’s eye, allowing for precise customization. This technology aids in the creation of lenses that fit comfortably, align with the eye’s natural contours, and provide optimal vision correction.

4. Color Matching and Artistic Expertise:

Achieving a natural and aesthetically pleasing appearance is a crucial aspect of designing prosthetic contact lenses. We, often collaborating with skilled artisans and technicians, meticulously match the color and pattern of the artificial lens to the patient’s healthy eye. This requires both technical expertise and artistic skill to ensure a seamless integration.

5. Iterative Design Process:

Designing prosthetic contact lenses is an iterative process that involves several steps. The initial design is reviewed and refined based on feedback from the patient. Multiple fittings and adjustments may be necessary to achieve the desired outcome. Other designs are made only once. We work closely with the patient to ensure their satisfaction and comfort throughout the process.

6. Manufacturing and Quality Control:

Once the final design is approved, the manufacturing process begins. Specialized laboratories utilize high-quality materials to fabricate the prosthetic contact lenses. Quality control measures are implemented to ensure precision, accuracy, and durability. Each lens undergoes thorough inspection before it is deemed ready for the patient.

7. Fitting and Follow-Up:

After manufacturing, the prosthetic contact lenses are fitted onto the patient’s eye. We assess the fit, comfort, and visual acuity provided by the lenses. Follow-up appointments are scheduled to monitor the patient’s progress, address any concerns, and make any necessary adjustments to optimize the fit and performance of the lenses.

The design process of prosthetic contact lenses is a delicate balance between science and artistry. It involves careful measurements, advanced technology, artistic color matching, and iterative adjustments. With the our expertise and skilled technicians, these lenses provide both functional and aesthetic benefits, helping individuals regain confidence and improve their quality of life.